For each glass manufacturer, the use of cullet (recycled glass) is very beneficial in many ways e.g. energy consumption reduction, CO2 waste gas reduction, reduced landfill. The most important disadvantage of using cullet is the risk for glass quality decrease due to contaminated cullet. The enormous quality gap between the input waste glass and output of a glass recycling plant, the quality fluctuation of the input waste glass and the possible failures (e.g. poor adjustment) of the high tech equipment of the cullet treatment plant result in an eminent risk for the glass manufacturer to contaminate its glass melt with cullet of (very) poor quality.

Consequently, the cullet quality control procedures have a very high impact on the quality level and performance of the cullet treatment plant and on the final glass quality at the glass plant. As this quality control is time consuming (and costly), the glass quality control procedures at the cullet treatment plant and at the glass plant need to be optimised so that the best guarantee on the quality of the cullet can be given at the lowest cost.

As cullet is for many glass manufacturers one of their most important (secondary) raw material, quality control (QC) errors must be kept to a minimum. For cullet treatment plants and glass plants familiar with 6 sigma quality objectives, a 95% reliable (≈2σ) cullet QC is a must. However, our calculations prove that probabilities of making quality control errors are usually much higher, resulting in unacceptable producer's and consumer's risks.

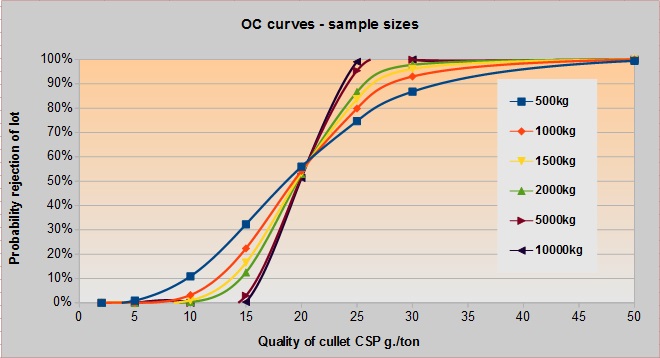

Using our statistical calculation programs, taking into account cullet quality specifications, sample size(s), grain size distribution and weight of the contaminating pieces, we determine the operating characteristics curve(s) and the corresponding acceptance and rejection conditions according agreed maximum risk level(s). Combining cullet quality specifications and agreed maximum producer and consumer risk level, a fair, transparent, verifiable and statistical relevant cullet quality control procedure will be developed.

Interested in a free copy of our publications 'Cullet quality control' (Glass International March 2013) and/or 'Reducing risk in cullet quality control' (Glass International April 2016)? Please check the "Free utilities - Tools" button on our "Home" page.