Glass Technology Courses

“Knowledge not shared is knowledge wasted.” We are pleased to share with you our glass technology knowledge and vast practical experience.

5 great reasons why you should choose GEM-Projects for glass technology training:

✔ Our courses are based upon our profound glass technology knowledge and, even more important, based upon our vast +30 years of practical experience in glass chemistry, glass melting and glass forming.

✔ GEM-Projects is a 100% independent glass technology service provider: no hidden agenda promoting or selling software, measuring devices or equipment.

✔ We offer a wide range of unique, live e-learning courses, including courses for glass industry suppliers and food & beverage industry using glass packaging.

✔ Our courses are custom made, cost and time effective courses, perfectly adapted to the needs, education level and experience of the participants.

✔ As a small company, we offer a high degree of flexibility: content, duration, on-site or e-learning, ...You decide and choose your best option!

A comprehensive range of courses and training programs:

Depending on the needs and wishes of your company or organisation, GEM-Projects can deliver on-site training courses such as a one day 'Glass technology essentials' course or develop further courses which tailor the content specifically to your needs, covering topics as

A comprehensive range of courses and training programs:

Depending on your organisation’s needs, GEM-Projects delivers on-site training such as a one-day “Glass Technology Essentials” course, or develops fully tailored programs.

- Glass chemistry and glass physics: viscosity, crystallisation, strength, optics.

- Raw materials and batch calculations; batch mixing and handling.

- Glass melting, furnaces, furnace operation and control.

- Glass forming processes.

- Hot-end and cold-end surface treatment; annealing.

- Cold-end operation, defects and glass quality.

- Glass recycling, cullet quality and environmental issues.

- Glass packaging for pharmaceutical and food & beverage industries.

Examples of courses include:

For managers and investors: a “Glass Manufacturing Essentials” course covering batch cost optimisation, furnace energy cost, product quality and plant organisation.

For IS-machine operators: training focused on forming processes, viscosity behaviour, fabrication parameters and defect troubleshooting.

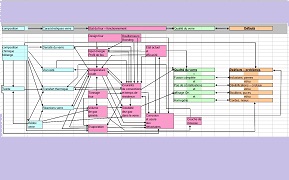

For glass technologists: practical training in batch calculation programs (including open-source solutions) and optimisation of batch formulas.

For food & beverage companies: supplier follow-up programs explaining packaging production, strength, stress, thermal shock, breakage, quality assurance and insider knowledge.

All courses include real-world examples, tips and practical guidance, tailored to participant needs.

In-house training at your company or an interactive e-learning experience?

We usually bring our training courses to you. In-house training allows us to tailor the content and address your actual production issues directly.

GEM-Projects also offers cost-effective live online training programs (1–4 hours), suitable for focused topics such as batch calculations, colour measurement, furnace operation, defects, glass strength and breakage.

All training courses are available in English, French or Dutch.

Take this unique opportunity to learn from our 30+ years of worldwide glass technology experience.