Project snapshots and some info

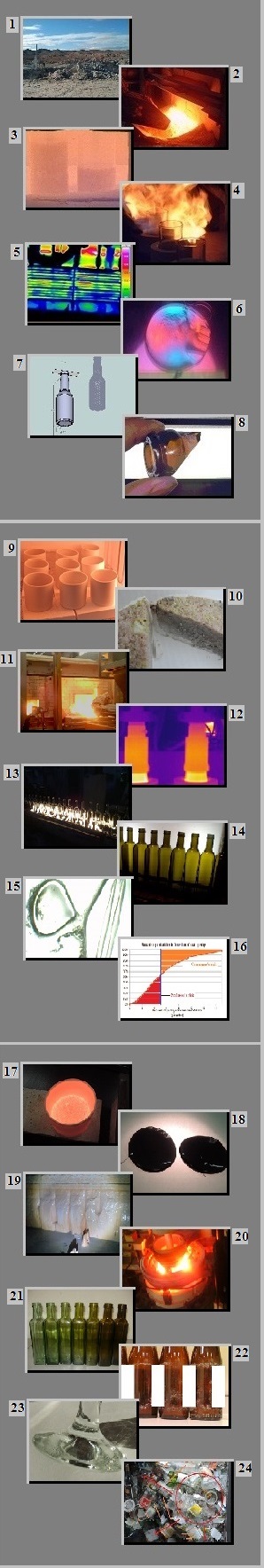

- Geological survey, exploring mineral deposits, market research and supply/demand analysis of raw materials for the glass industry - Picture 1: checking the quality of drilling samples.

- Glass furnace energy efficiency audit and optimisation of the furnace control strategy to reduce the specific energy consumption - Picture 2: batch charger of a small unit melter furnace.

- Batch recipe optimisation, solving glass melt foaming problems and improving the fining efficiency of a glass melt - Picture 3: lab melting test, observing the different foaming behaviour between two chemically identical glass melts at temperatures above 1400°C.

- Glass production energy efficiency assessment and energy consumption reduction - Picture 4: fire polishing being a minor parameter in the total energy consumption of table ware glass production.

- Glass fibre and glass wool production optimisation and trouble-shooting - Picture 5: IR measurements of the bushing temperature distribution as poor temperature homogeneity is often a cause of fibre breakage.

- Float glass quality problems, glass failure and glass defects trouble-shooting - Picture 6: polariscope analysis of stress caused by vitro-ceramics contamination in float glass melting test samples.

- Technical assistance to food and beverage industry for container

glass design, glass container quality specifications and glass

packaging trouble-shooting - Picture 7:

light-weight and glass packaging optimisation for a world-top brewery;

development of full 3D design of bottles including capacity and weight

optimisation calculations.

- Glass production and glass quality follow up at the glass plant, statistical quality control, glass quality audits for food and beverage industry - Picture 8: a very small filament (i.e. a hair-like glass string) at the inside of the finish, a highly critical defect, totally invisible for the automatic inspection was intercepted and eliminated 'at the source' avoiding a critical needle-shaped glass particles contamination of beer bottles.

- Batch recipe and glass chemistry optimisation studies using lab tests. Melting and dissolution processes of different batches were analysed. These tests proved to be very useful comparing the melting and fining efficiency of different batches, testing or verifying the benefits of using one raw material compared to another and/or analysing or verifying the benefits of new raw materials introductions. Our melting test procedures enables to determine the intermediate crystalline phase steps of the glass melting process and to determine the velocity of the dissolution and glass melt generation process. - Picture 9: melting tests - nine batch samples in an electric furnace.

- Studying the batch-glass transition process; batch melting and glass melt forming efficiency improvement studies - Picture 10: batch - glass-melt sample for glass transition process analysis

- Glass furnace melting and fining trouble-shooting; assessment of furnace design and furnace operation - Picture 11: small glass furnace for luxury fragrance and cosmetics bottles.

- Improving the glass forming process and glass forming defects trouble-shooting - Picture 12: infra-red image of a table-ware forming process.

- Improving the pack to melt ratio of container glass production - Picture 13: bottles being reheated before entering the annealing lehr.

- New colour production assistance eventually including lab melting tests for unique 'first time made' colours e.g. grey, purple, cobalt or copper blue, black, ...; glass chemistry, raw materials selection and batch recipe elaboration; colour change assistance and follow-up of the first production of the new colour. - Picture 14: Perfect quality olive green glass bottles made for the first time at a Middle East glass plant.

- Glass melting and fining trouble-shooting; solving blister and/or seeds problems; solving chemical and physical reboil problems - Picture 15: microscopic detail of blisters.

- For both glass recycling companies and glass manufacturers using high cullet ratio batches, it is extremely important to have an excellent accurate and precise cullet quality control procedure. Using our unique in-house developed statistical calculation program, we give you a clear insight in the risk percentage to accept a non-conform cullet quality for a given QC procedure. Using statistical calculations, we optimise and improve the cullet quality control procedures used at the glass plant and/or at the cullet treatment plant to reach a wanted level of precision and accuracy. - Picture 16: the operating characteristics curve calculated for a cullet quality control procedure showing the producer's risk and the consumer's risk of a cullet quality control procedure that could be significantly improved.

- Lab glass melting tests for melting and/or fining improvement; new batch formula and new raw materials or unique glass colours development, etc... - Picture 17: glass sample taken out of the lab furnace for further analysis.

- Definition and elaboration of new, exclusive glass colours for high-end container glass production. - Picture 18: a unique dark purplish colour for exclusive liquor bottles.

- Technical evaluation of glass furnaces and glass production process, glass furnace performance audit and/or energy efficiency benchmark using our database containing hundreds of records of glass furnaces from all over the world. - Picture 19: inside a container glass furnace with highly corroded AZS refractories and an almost completely corroded barrier wall.

- Glass melting process audit, analysing and optimising the glass melt flow pattern, minimum residence time and/or temperature profiles in furnace and forehearths - Picture 20: inspecting the glass melt at the spout.

- Colour change assistance and colour change procedure optimisation using our vast experience from dozens of colour changes. Using our batch recipe modification procedure and furnace settings strategy, we minimise transition time, glass quality losses (blisters, foaming, ...) and 'out of colour specs' production losses. In favourable conditions, using our advanced techniques for redox changes and applying overdose techniques,the transition time can be less than 12 hours for a 100tpd furnace - Picture 21: samples from a very fast colour change.

- Glass technology assistance to food and beverage companies, solving glass packaging problems, reducing glass breakage and/or giving independent advice, assistance or glass technology training. - Picture 22: analysing the scuffing of beer bottles and advising a world top brewery for improving the glass coating to minimise the scuffing of their returnable bottles.

- Improving glass quality of table-ware e.g. extra clear flint glass production; solving glass quality problems and eliminating glass defects. - Picture 23: fabrication defect on the base of stemware.

- Glass breakage expertise; expert witness; glass breakage assessment. - Picture 24: detailed study of all parameters having impact on the glass breakage throwing bottles and jars in large glass recycling containers. Based upon the results of this study, an improved design of these recycling containers was elaborated and tested. Results showed a significant decrease of the glass breakage. Glass recycling companies highly prefer bottles and jars with a low degree of breakage as unwanted impurities like ceramics and vitro-ceramics can be sorted out much more efficiently.